Services overview

Egaturbo is a proven pump solutions

Egaturbo with services division (Egaturbo) is a service provider for all types and brand of pumps that offers spare parts, repairs/ overhauls, upgrades, reverse engineering and customer training for ANSI process pumps, API 610 pumps, HPS pumps, submersible pumps, pump packages, and Industrial IoT to the oil and gas, power generation, chemicals and general industrial.

With our expertise in pump manufacturing, we understand the critical factors for trouble-free operation. We optimize pump performance and longevity to ensure our customers achieve reliable results at the lowest operational cost.

Egaturbo comprehensive service approach. Egaturbo technical services are experienced with servicing all types and brand of pumps and system design knowledge, and fully equipped with the latest design, analytical and pump testing equipment, our technical services team can be employed across a range of services to ensure your critical rotating plant is operating reliably, safely and at optimal levels of efficiency as our comprehensive service approach. Working in partnership with our customers, the focus of these important aspects of pump operation deliver increased mean time between failures (MTBF) and plant life, reduced parts consumption, increased production and very importantly, minimize energy costs and carbon emissions.

Professional engineering team

Egaturbo has a engineering team who can advise our customers to provide solution for any issues relating to pumps.

Experienced hydraulic team

Egaturbo can perform pump upgrades and reverse engineering to increased capacity or efficiency by replacing parts or by creating a completely new custom hydraulic design.

Qualified service engineers team

Egaturbo offers comprehensive quality service engineers for the maintenance, repair/ overhaul of pumps, and training for both on customer field and in our facility.

Engineered service solutions

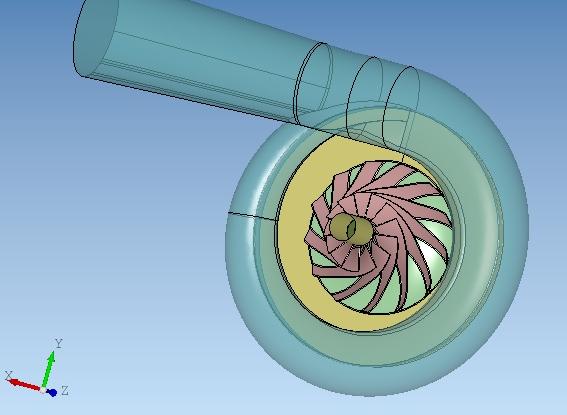

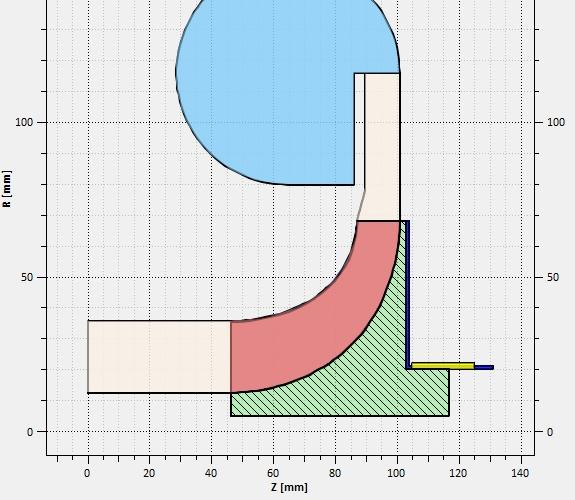

Hydraulic design process. The performance of a centrifugal pump is firstly determined from the heart of every pump which is formed by the impeller rotating in the pump casing. Together, the impeller and casing determine the flow characteristics of a pump. Once the hydraulic performance of the pump has been optimized, a thorough mechanical and dynamical analysis by means of FEM/ CFD analysis form the basis for a solid mechanical pump design, which guarantees long mean time between maintenance and service periods.

Hydraulic re-design to address process changes. Essential to any pump’s operation is its hydraulic performance. This is measured in flow, pressure and power consumed. Egaturbo flow technology’s unrivalled technical expertise means that we are able to re-design any installed unit in order to optimize its operational requirements. In the majority of cases, this can be done by finding an alternative hydraulic setup that already exists. We can also supply fully optimized clean sheet designs, using the latest software tools.

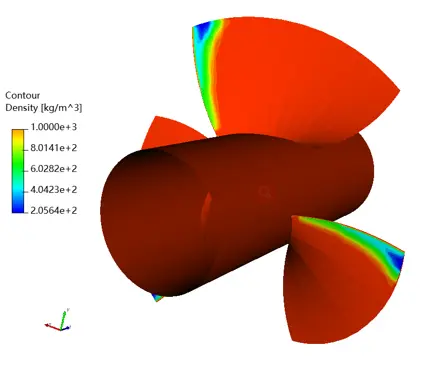

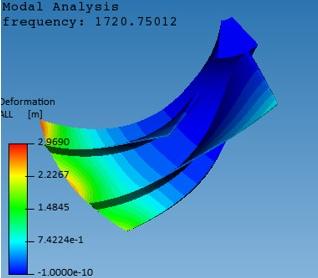

Advanced simulation. Egaturbo expert engineers performs all stages of the pump design process from the preliminary design to flow simulation and preparation of final reports. We begin to establish specific requirements and goals for performance, reliability, manufacturability, and cost. Then, using state-of-the-art engineering techniques and analysis tools, we will create a design to meet our customer specifications. Afterwards, we will provide the CAD solid modeling of the designed flow path and manufacturing drawings. Our collective experience covers all branches of pump design and related fields of knowledge including: hydraulics design, CFD, FEM, and rotor dynamic analysis.

Hydraulic design

State of the art CAE methods for fast design exploration and optimization.

Flow simulation - CFD

CFD techniques can greatly reduce the time needed for product development.

Structural analysis - FEA

FEA simulation to accelerate product development with confidence.

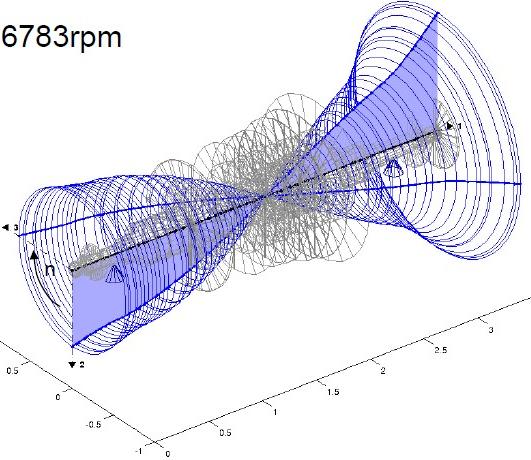

Rotor dynamic analysis

Rotor dynamic analysis will help maintain reliability and stability of pumps.