Upgrades

Egaturbo upgrades services (ETS-UPGRADES)

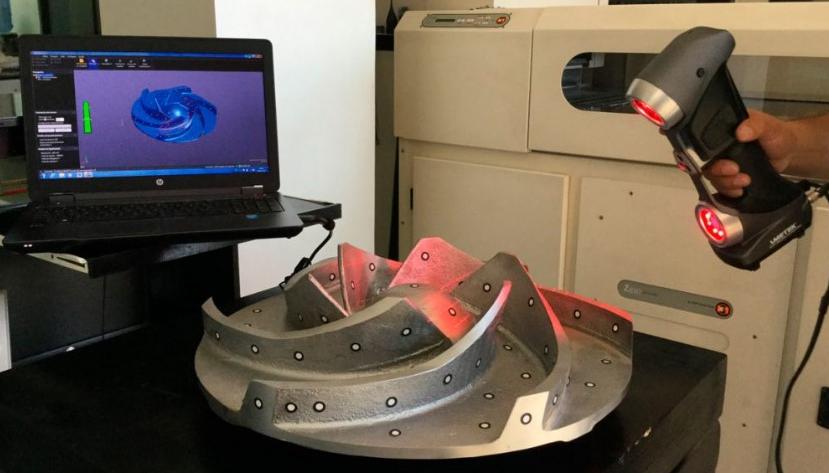

Egaturbo upgrades services ensure the ongoing performance and reliability of all types and brand of pumps and we help protect the value of our customer assets through upgrades to minimize capital expenditures and maximize performance and reliability.